Laser marking

Precision marking of multiple materials, from corrosion resistant black marking of stainless steel to micro marking of glass and polymers. Multi-color marking technology for metals and ceramics.

Marking of logo, serial numbers, QR, bar and data matrix codes on mobile phones, wristwatches, jewellery and medical instruments.

Laser marking has several advantages over traditional marking methods, making it the best option for industries that require precision, durability, and high-quality finishes. The process is contactless, resulting in minimal wear on the equipment and no mechanical stress to the material. Unlike ink-based marking methods, laser marking is permanent and resistant to fading, corrosion, and environmental factors such as heat, moisture, and chemicals.

Furthermore, laser marking offers high-speed processing, allowing for more efficient production cycles in industrial settings. The ability to mark fine text, logos, and machine-readable codes ensures traceability in industries such as aerospace, medical, and electronics manufacturing. Laser marking is also an environmentally friendly and cost-effective solution for modern manufacturing needs, as it does not require consumables such as ink or chemicals.

How does it work?

Laser marking is a method that involves using a intensive laser beam to modify the surface of an object. This interaction causes a change in the material. Laser marking is a collective term for various processes like ablation, engraving, black marking, color change, foaming, etc. The choice of method depends on the material and quality requirements.

Methods of marking

-

Black marking. Black marking on stainless steel is a highly versatile technique when corrosion resistance is a critical factor.

-

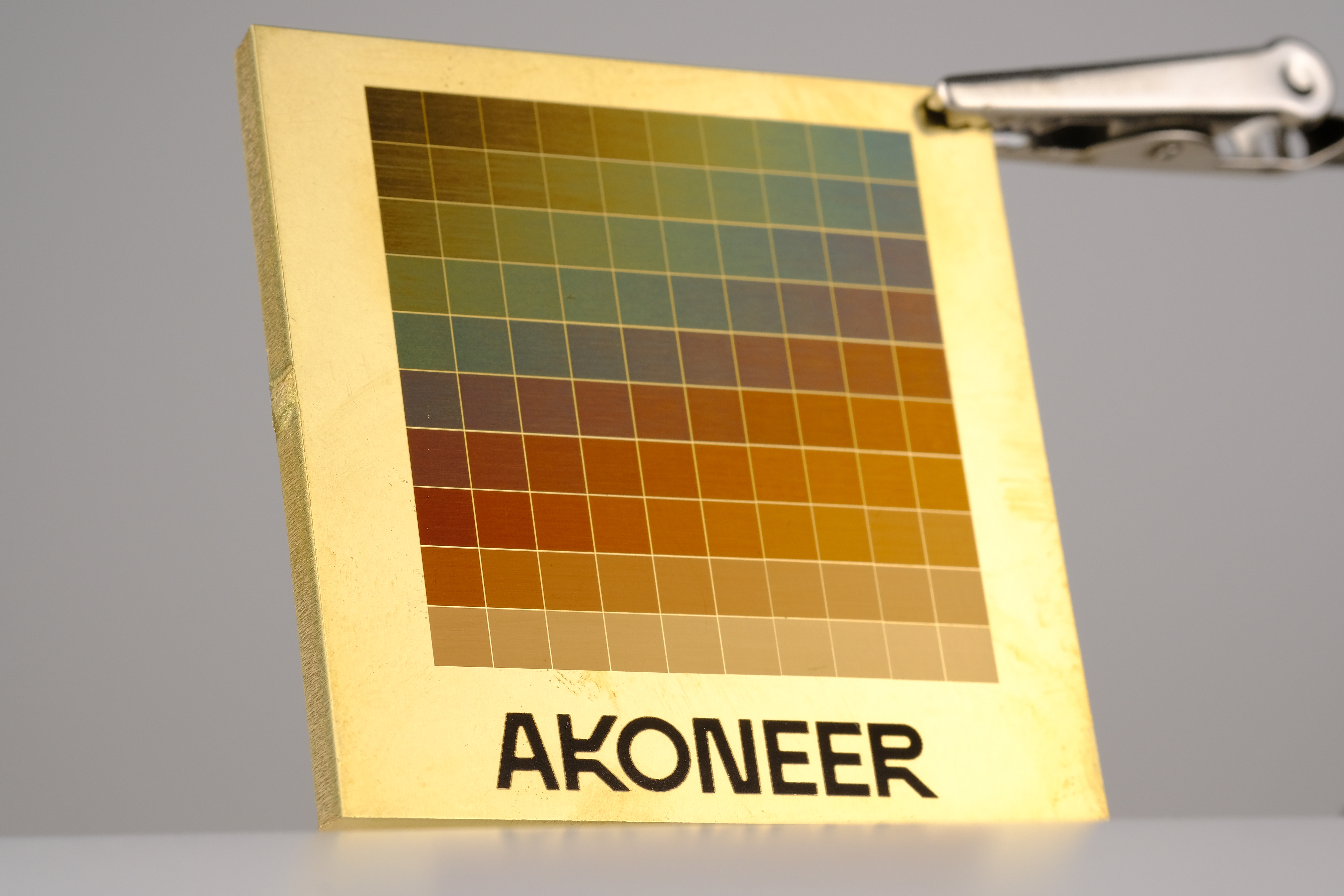

Multi-color marking. Laser multi-color marking is fast and flexible way to add graphics, designs, and images to enhance a product.

-

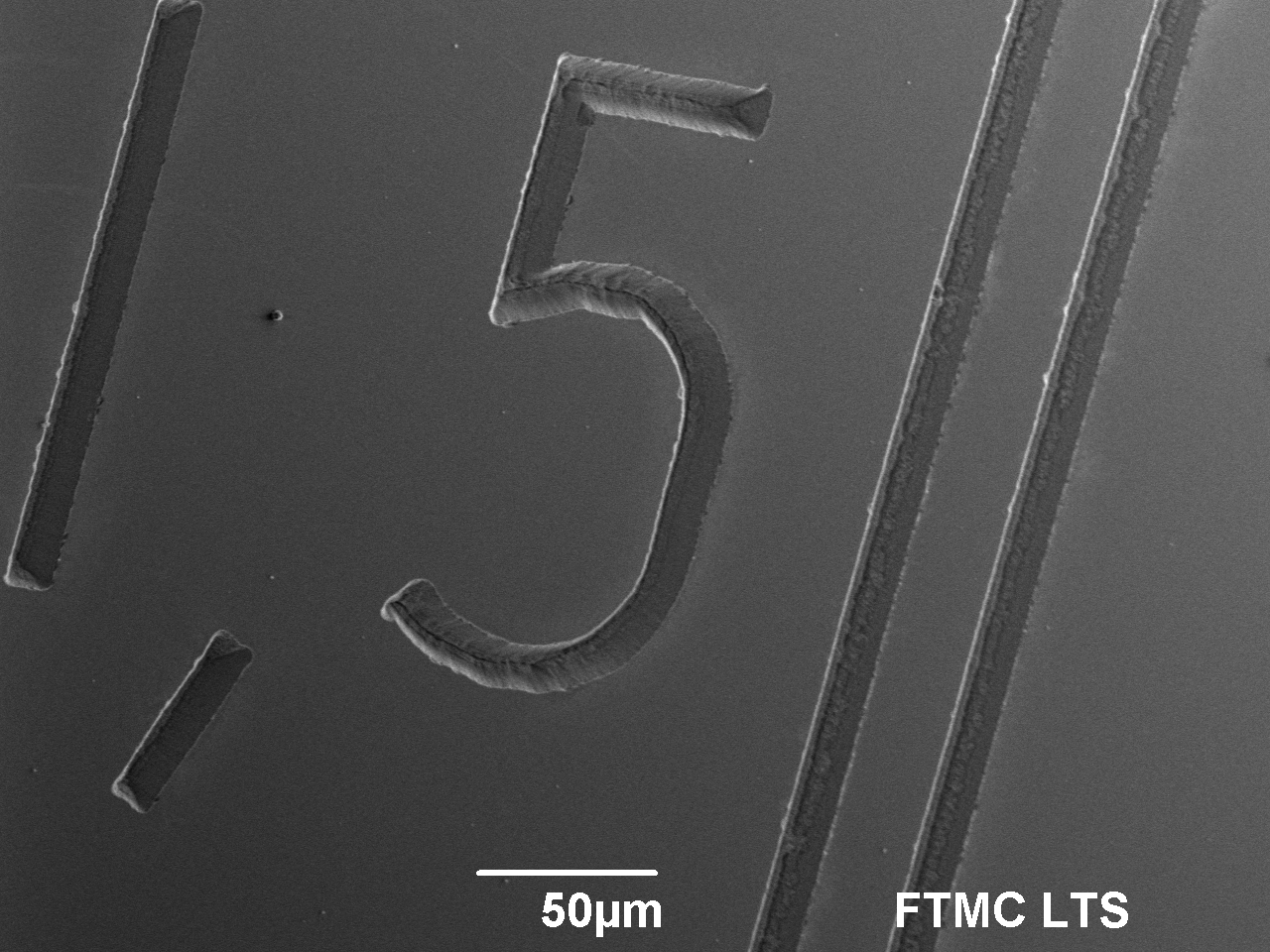

Micro marking. This method is attractive for industries where extremely high accuracy and miniature components are required.

Features

-

Permanent and high contrast mark on the surface

-

Up to 9000 mm/s processing speed

-

Laser marking is suitable for the whole range of materials: glass, metals, polymers, ceramics.

-

Micron level resolution process

-

No additive consumables

Materials

The following materials have been marked with our machines:

- Stainless steel

- Brass

- Titanium

- Aluminum

- Ceramics

- Polymers

- Glass and other transparent materials