Laser cutting

Laser cutting of various materials with micron level accuracy.

AKONEER provides machines for laser cutting of various materials with micron level accuracy. Depending on the requirements of the surface quality and speed of the cut, we select a suiting femtosecond or nanosecond laser source and cutting technology.

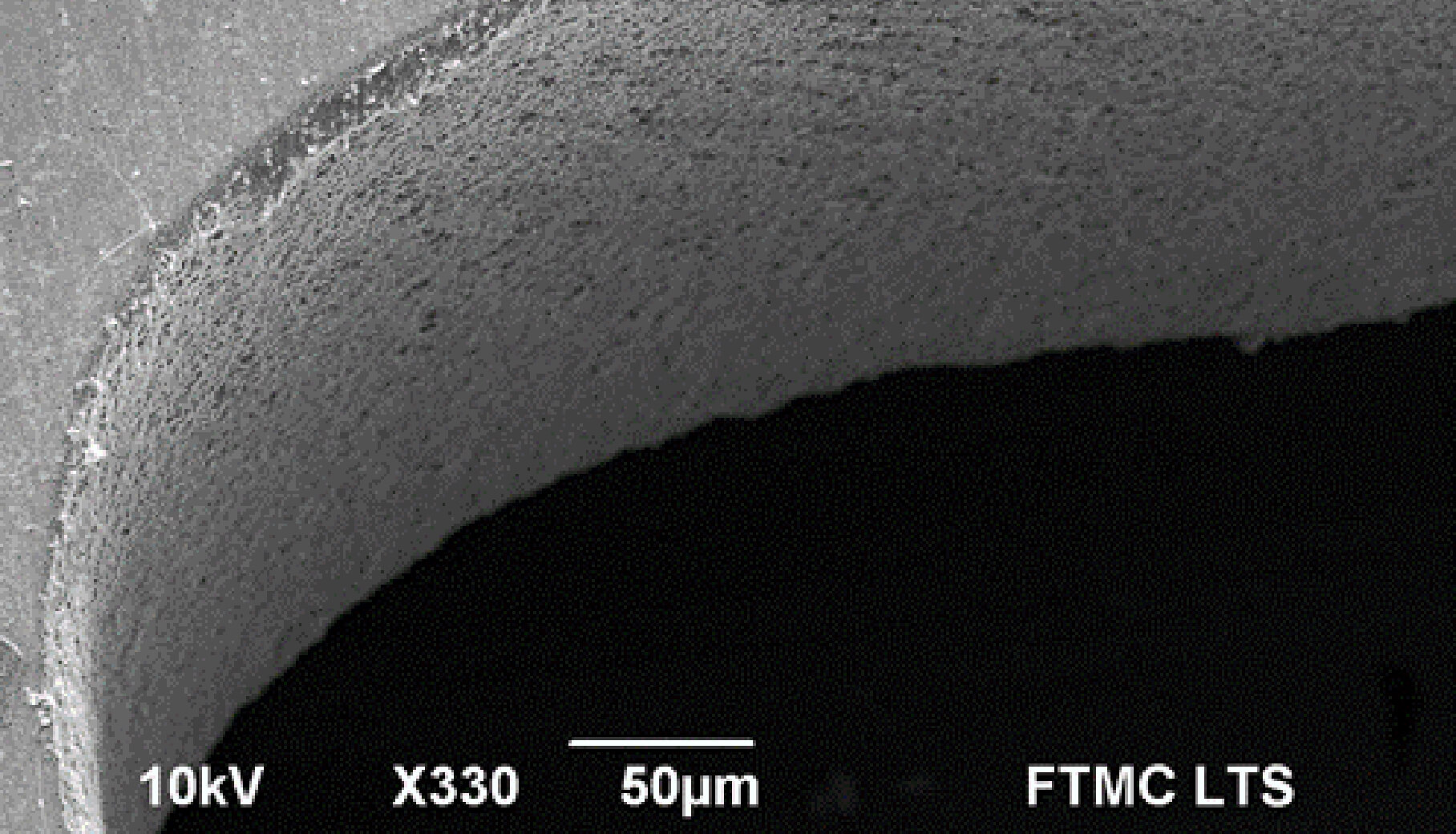

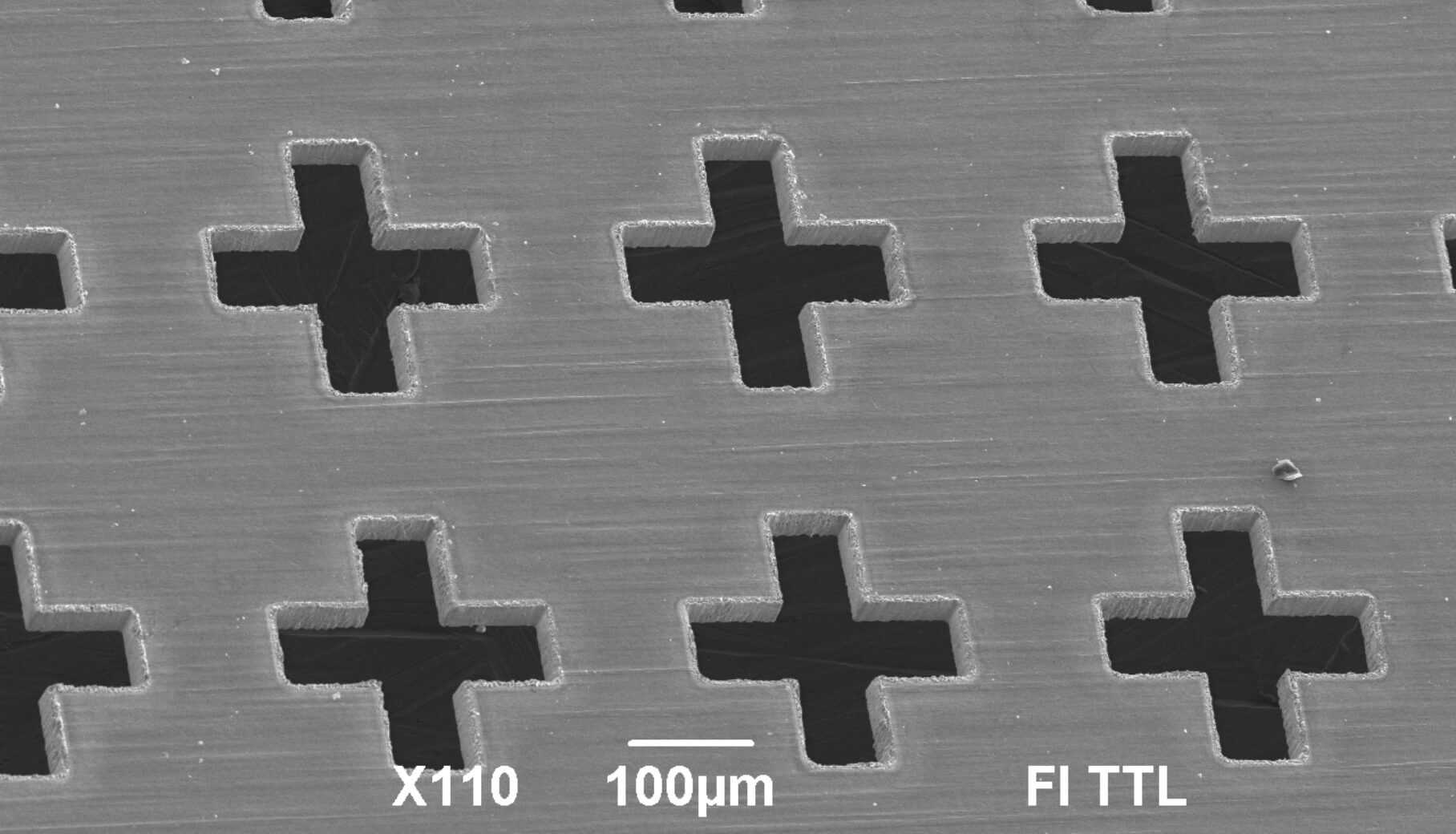

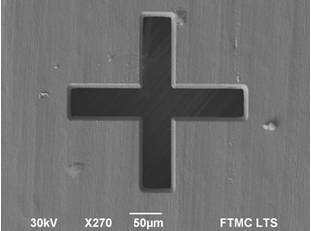

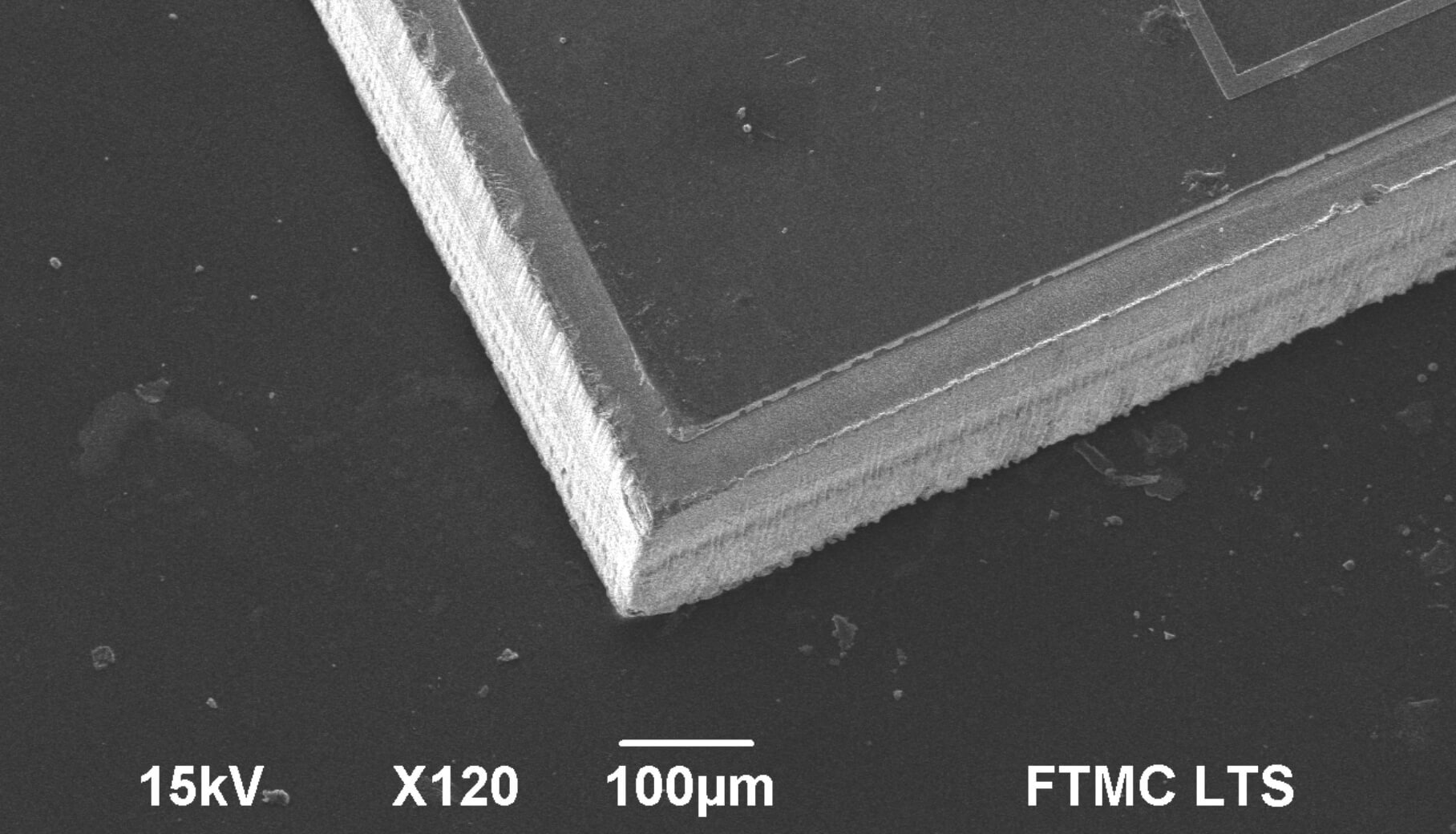

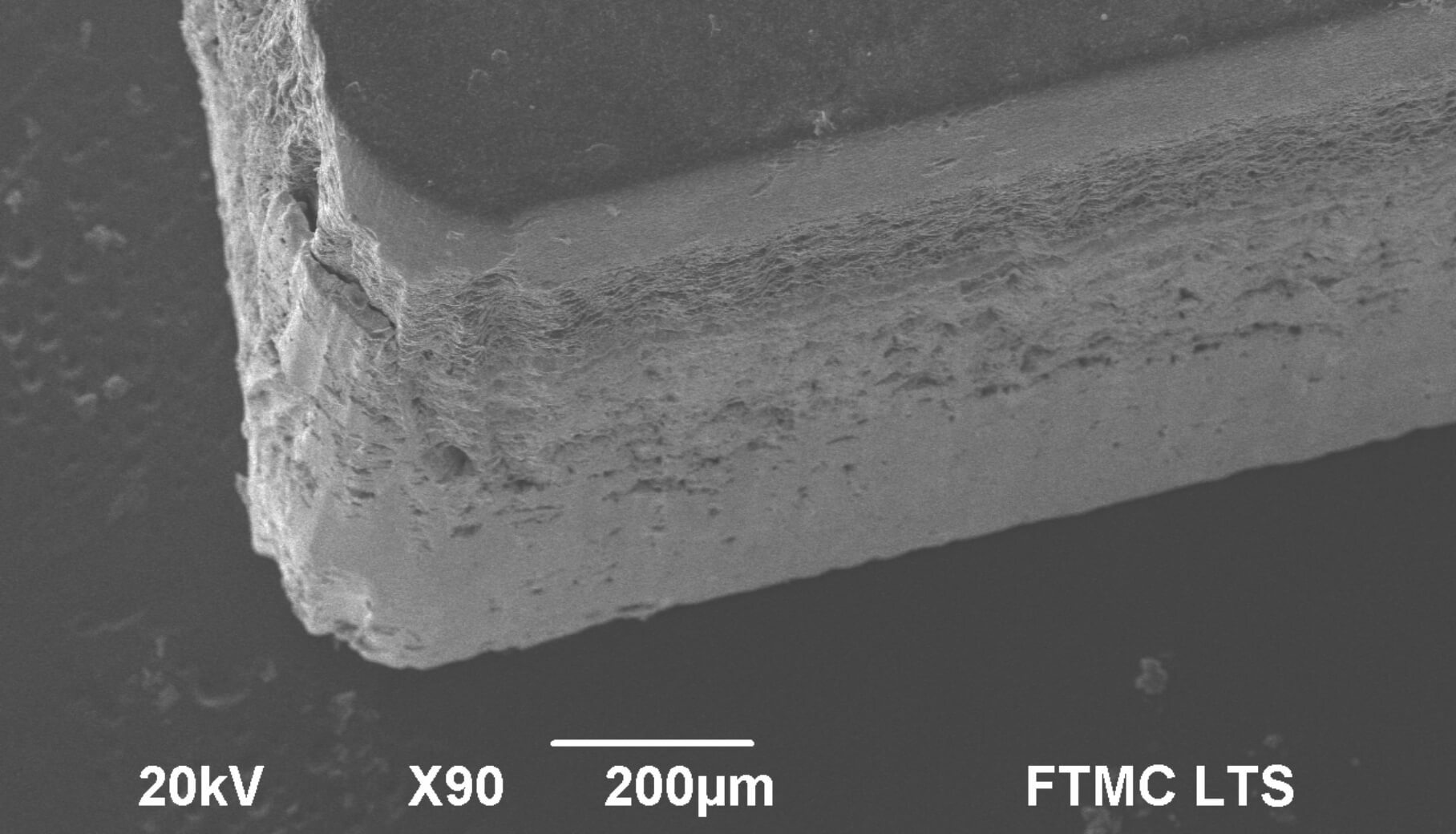

Femtosecond and nanosecond laser cutting provides a high-precision, non-contact technique for cutting various materials with micron-level accuracy. In contrast to traditional cutting techniques, laser cutting mitigates mechanical stress, decreasing tool wear and guaranteeing clean, burr-free edges. The cold ablation technique employed in femtosecond laser cutting reduces thermal effects, thereby averting material deformation, fractures, and heat-related damage.

This technology is especially advantageous for sectors necessitating complex and high-quality cuts, including electronics, medical devices, aerospace, and precision manufacturing. The capability to sever both 2D and 3D forms along adaptable paths facilitates the creation of intricate patterns and designs with superior consistency. Moreover, laser cutting accommodates a wide array of materials, including glass, ceramics, metals, polymers, and composites, rendering it a versatile option for sophisticated manufacturing applications.

Some of the materials cut with our machines:

- Glass (up to 20 mm thickness non tempered glass)

- Si and SiC

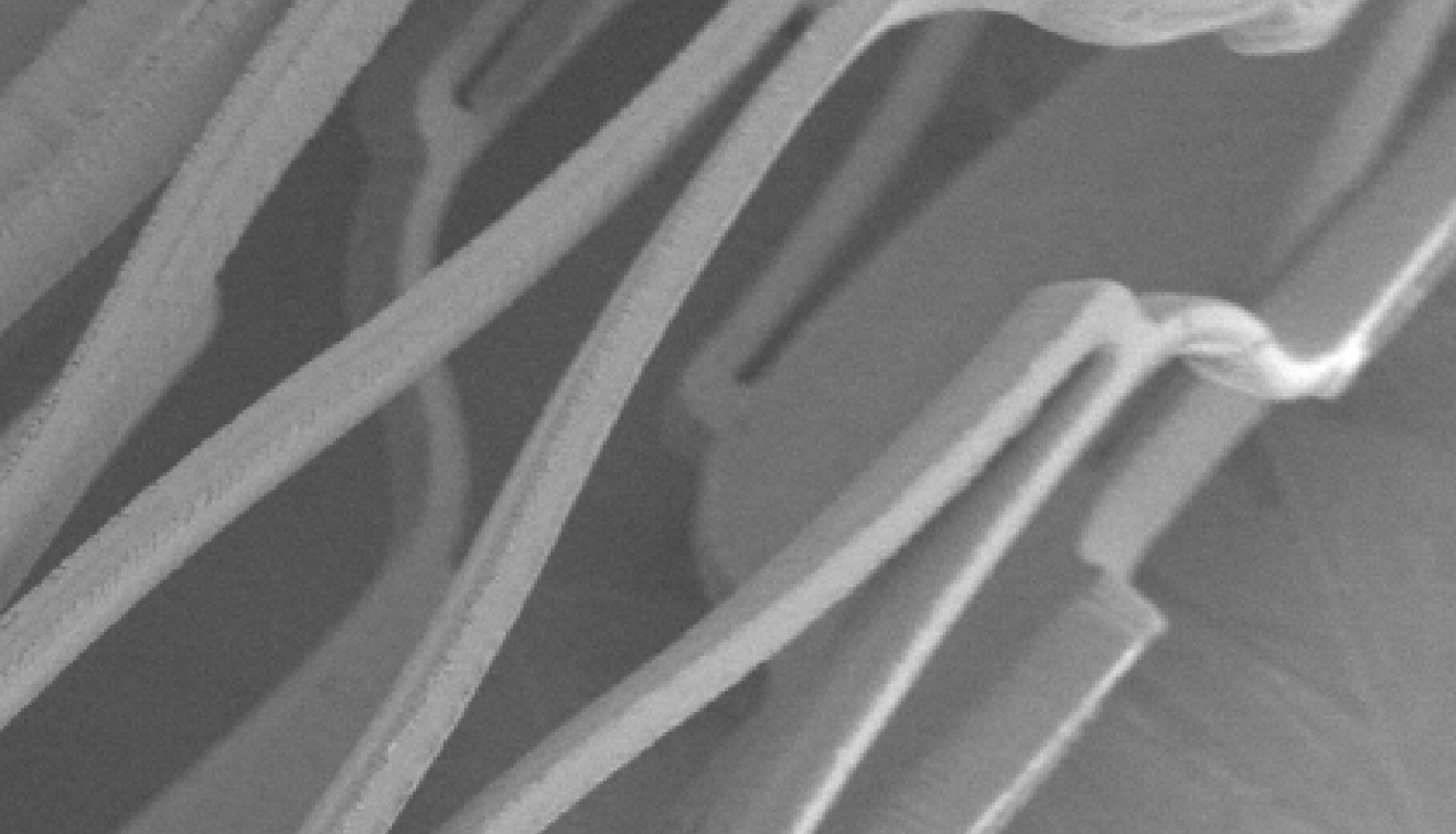

- Metal and polymer foils

- PCD and composite materials

- Ceramics

- Sapphire

- Various polymers

The femtosecond laser cutting process relies upon the principle of cold ablation. The application of this method minimizes the thermal impact on the material and avoids deformations.

Cutting can be performed on both 2D and 3D shapes, with the added advantage of flexible cutting trajectories. Versatile options such as circular, straight, or even intricate patterns can be cut, providing a wide range of possibilities for precise material removal.