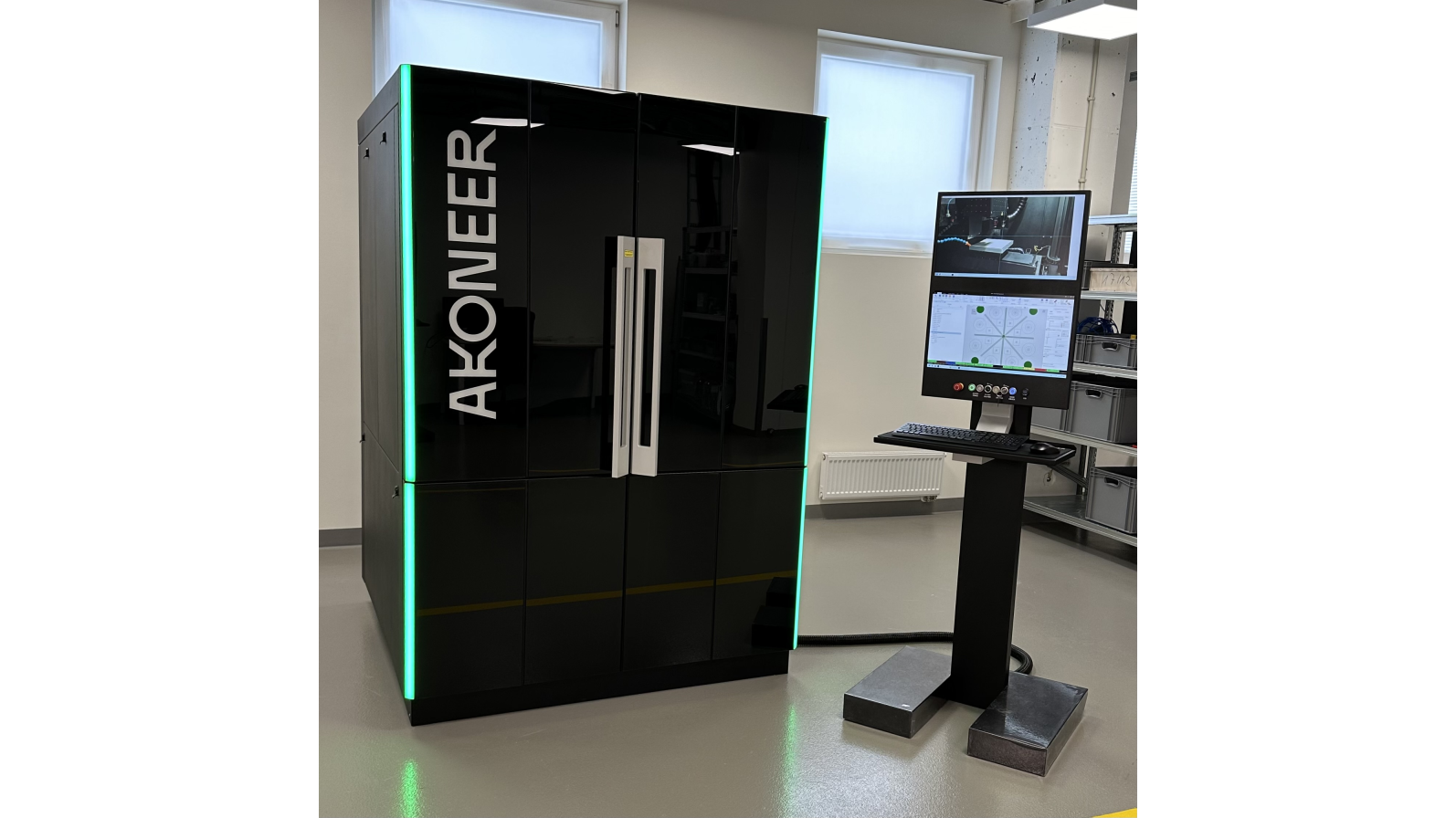

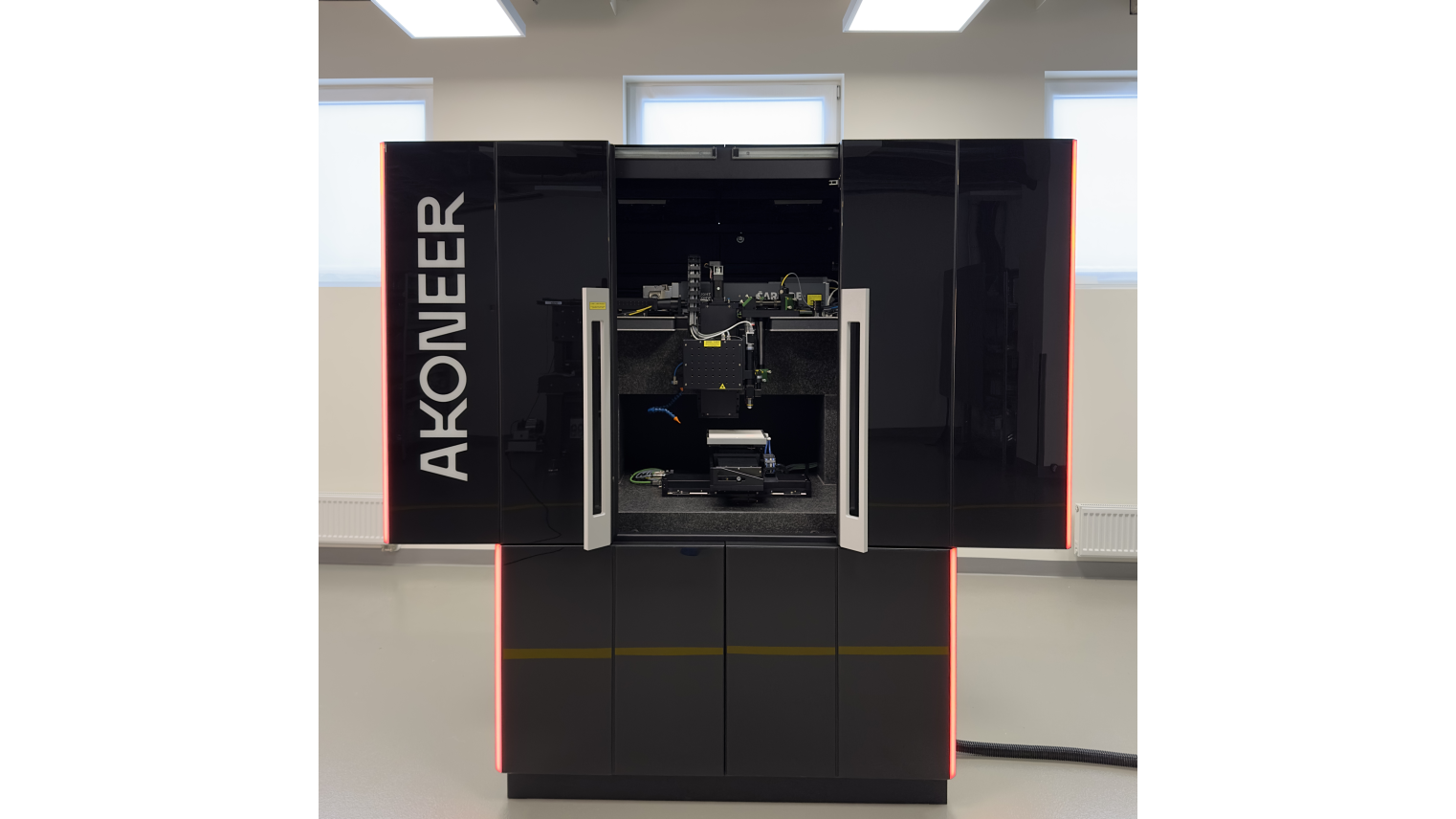

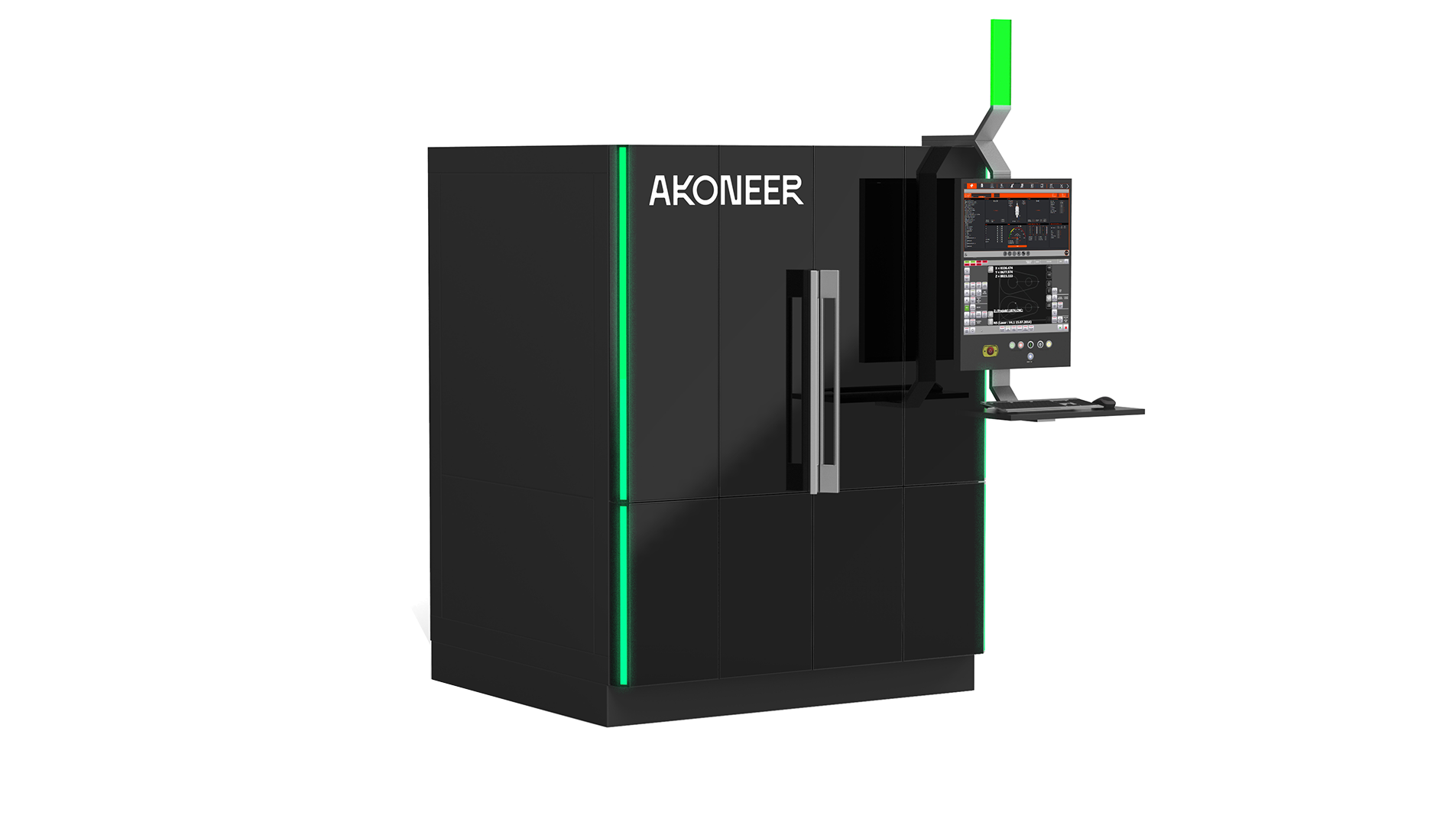

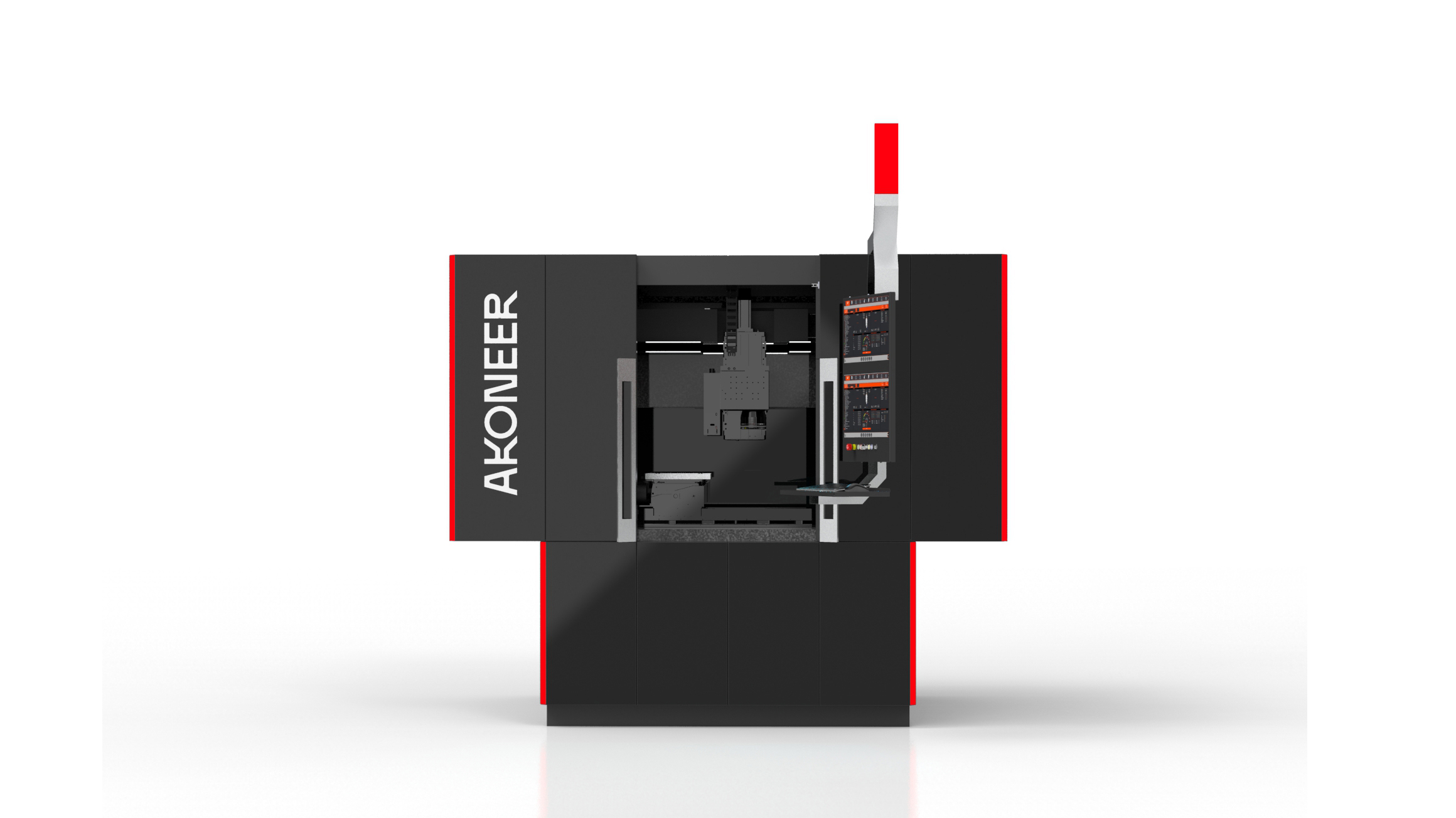

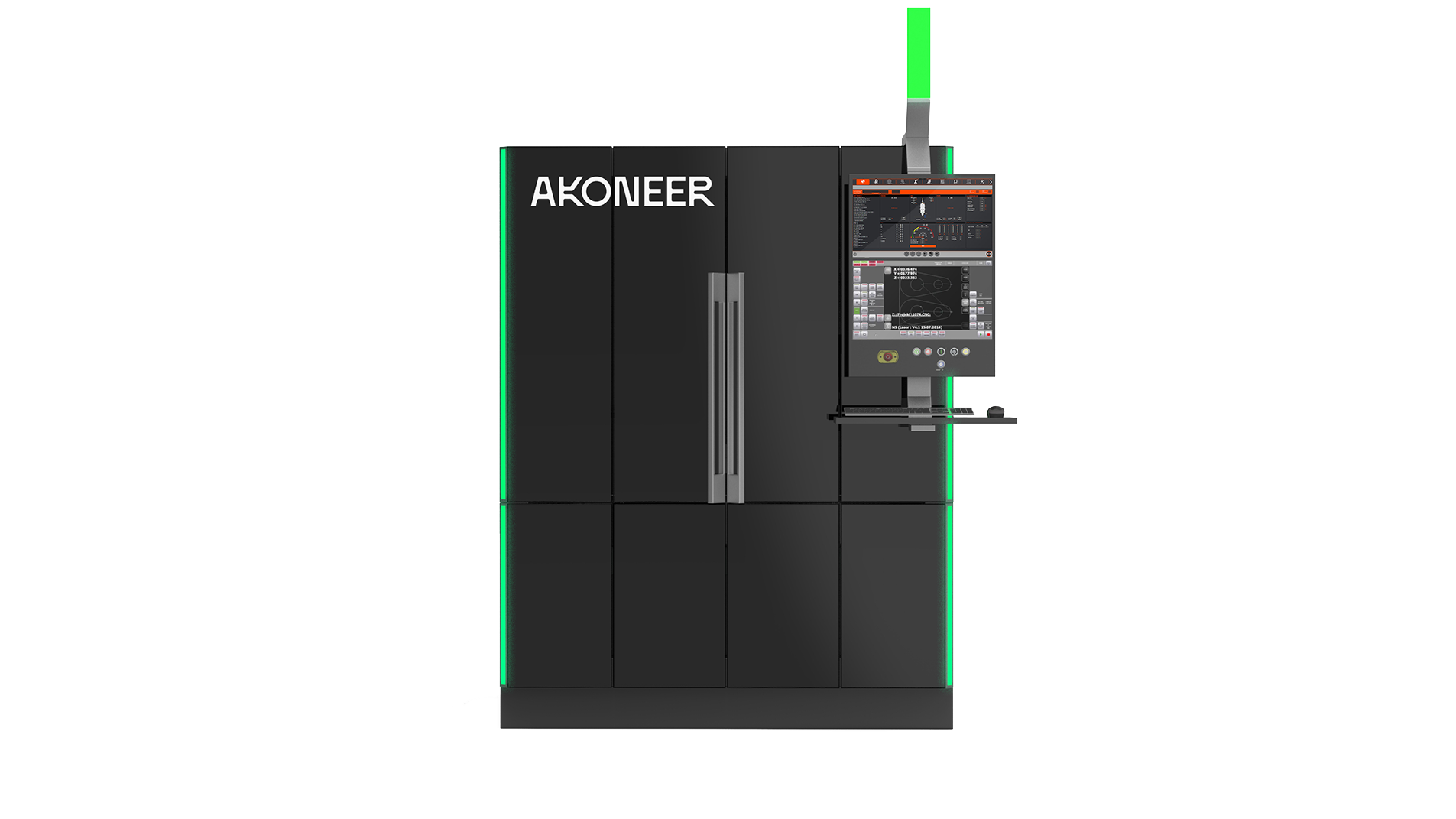

AKO 300

High precision laser micro machining workstation with working area of 300x300x200 mm. In a standard configuration it's equipped with femtosecond laser, high accuracy galvo scanner and machine vision. Our flexible platform allows easy customization of the configuration.