Laser drilling

Precise drilling of holes in a variety of materials, ranging from glass and plastics to metals and ceramics.

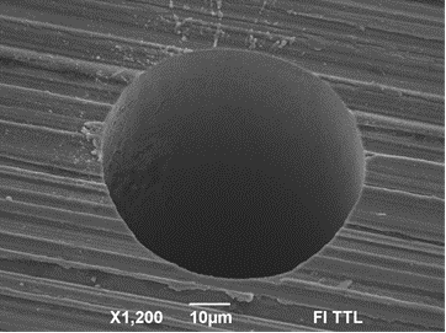

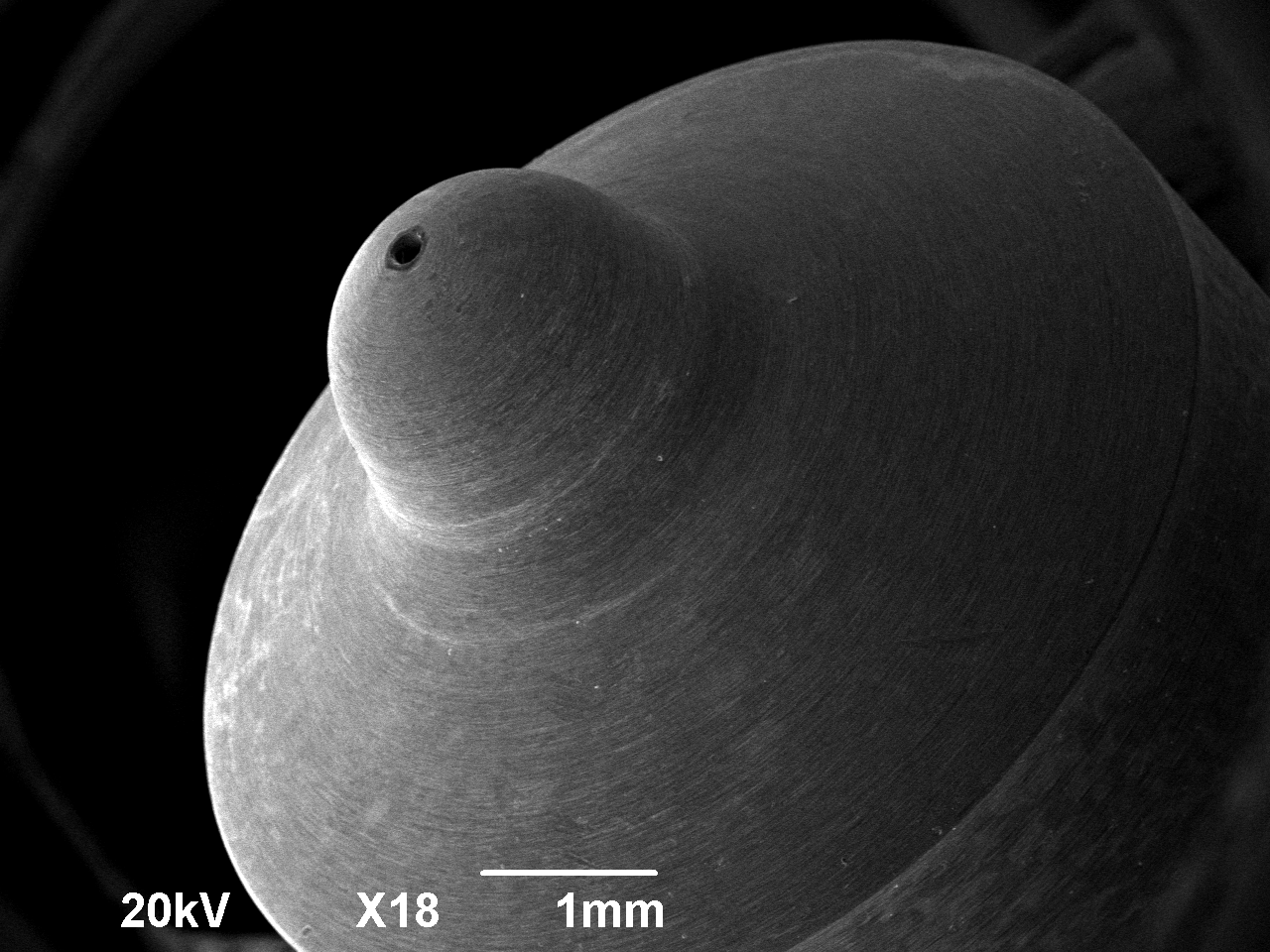

Laser drilling provides unparalleled accuracy and versatility, rendering it an optimal method for producing micro-holes in various materials. In contrast to traditional mechanical drilling techniques, laser drilling is a non-contact procedure that eradicates tool wear and diminishes the likelihood of contamination. Ultrashort pulse lasers minimize heat-affected zones, thereby preventing material damage and maintaining structural integrity.

Moreover, laser drilling exhibits significant versatility, enabling the creation of holes with diverse diameters, aspect ratios, and intricate geometries. It is especially beneficial in sectors necessitating micron-scale precision, including aerospace, medical devices, electronics, and automotive manufacturing. Laser drilling facilitates the penetration of hard, brittle, and delicate materials without necessitating post-processing, thereby improving efficiency, minimizing waste, and guaranteeing exceptional quality in high-precision applications.

HOW DOES IT WORK

As ultrashort pulse lasers are used to drill or cut through the material as the laser beam is concentrated precisely on the working area. As a result, evaporation of the material proceeds without the interim melting phase and any further postprocessing steps, such as burns and bulges elimination are not necessary.

FLEXIBILITY OF SHAPES

Drilling can be carried out on a diverse array of sample types, including both 2D and 3D structures, for example components like fuel injector nozzles.

MATERIALS

- Glass

- Ceramics

- Metals

- Polymers

- Sapphire