SLE

Selective Laser Etching to minimize tapering and surface chipping on transparent materials.

Release constraints on structure size and material thickness thanks to combining technology femtosecond lasers with chemical etching. Through local modifications, this process enables the direct fabrication of true 3D micro-devices within transparent materials.

HOW DOES IT WORK

Femtosecond lasers have the capability to selectively induce local modifications within transparent materials, owing to their strong nonlinear absorption. These internal modifications lead to structural and chemical changes that can be specifically eliminated by immersing the samples in aqueous solutions of etchants such as hydrofluoric acid (HF) or potassium hydroxide (KOH).

FLEXIBILITY OF SHAPES

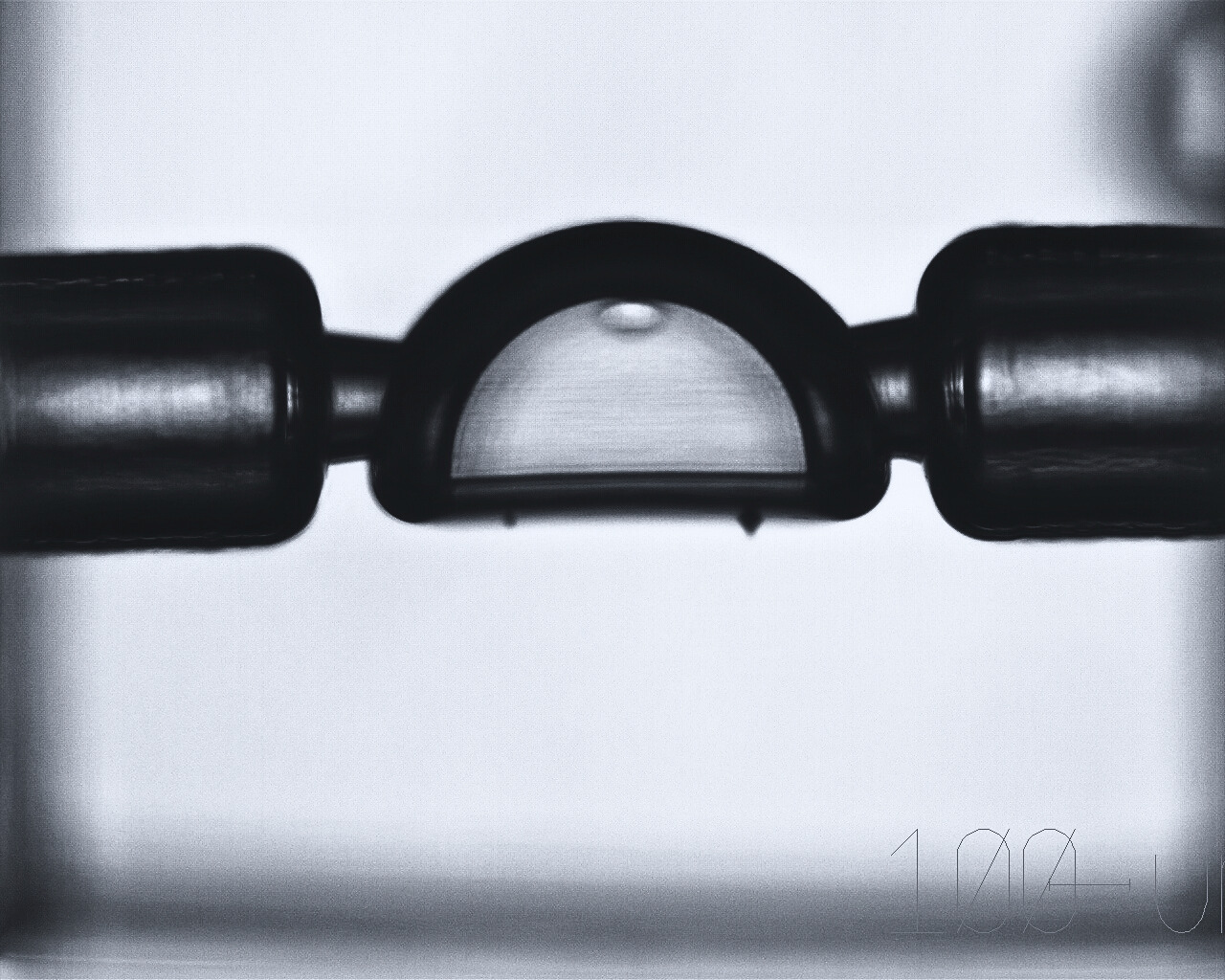

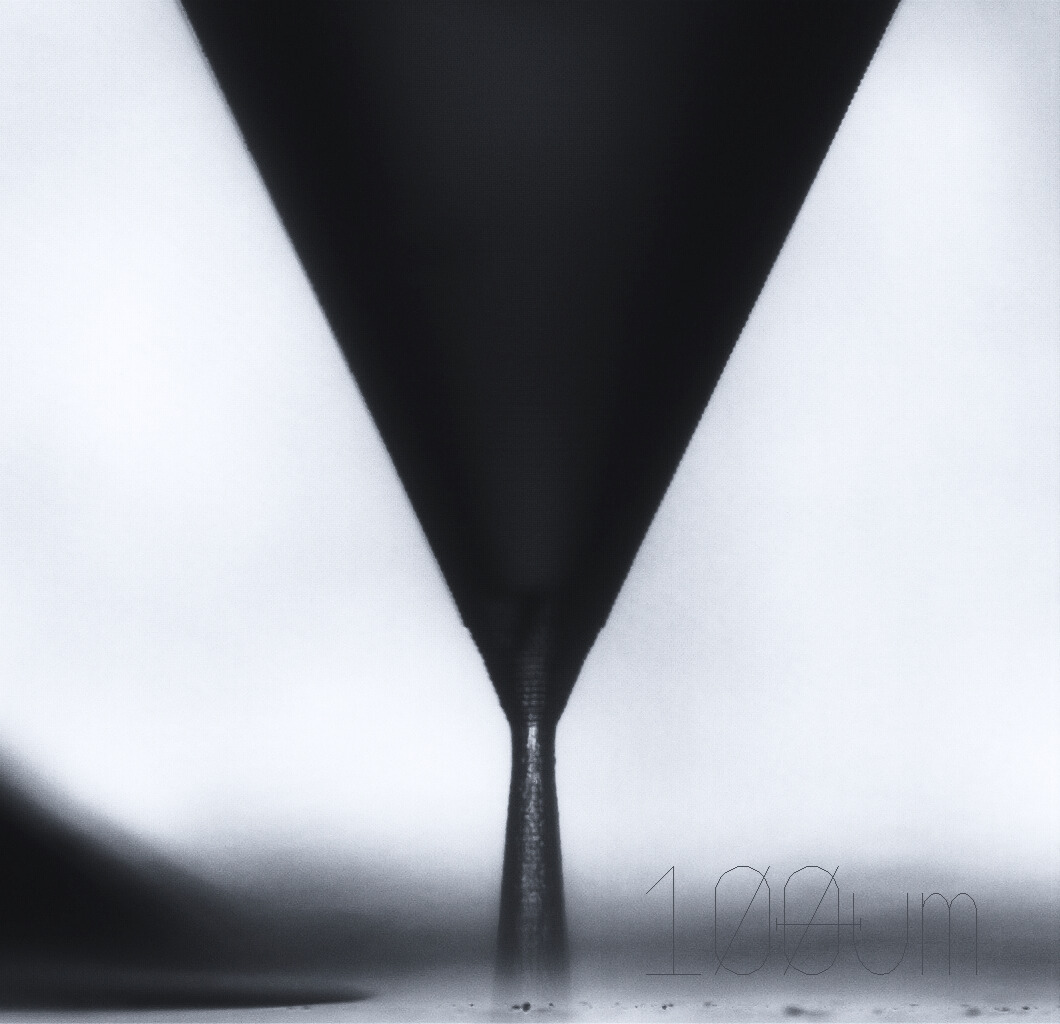

SLE technology can form various structures in glass, that includes:

-

Flat or free-shape 3D structures

-

Surface or internal channels

-

Microfluidic channels

-

Capillary nozzles

-

Lenses

-

Various micromechanics elements

-

many other...